SOURCING OUALITY

The majority - 90 percent - of our components are purchased from factory and franchise-direct. The remaining 10 percent are purchased through qualified OEM/CM partners, who must pass rigorous background checks to ensure their product quality is on par with the demands set by BISON. By ensuring our component sources share our quality control values, we dramatically increase the likelihood that the components that move forward to the testing process pass without issue. But that doesn't mean testing is lax.

COMPONENT TESTING

Our product testers combine extensive training and years of experience in detecting counterfeit and poor-quality parts. Their skills, combined with our in-house testing facility, which is fully equipped with the latest equipment, allow us to conduct a full spectrum of quality assessments. Every product that passes through our facility undergoes a rigorous 58-point inspection that is compliant with the IDEA-STD-1010-B standard.

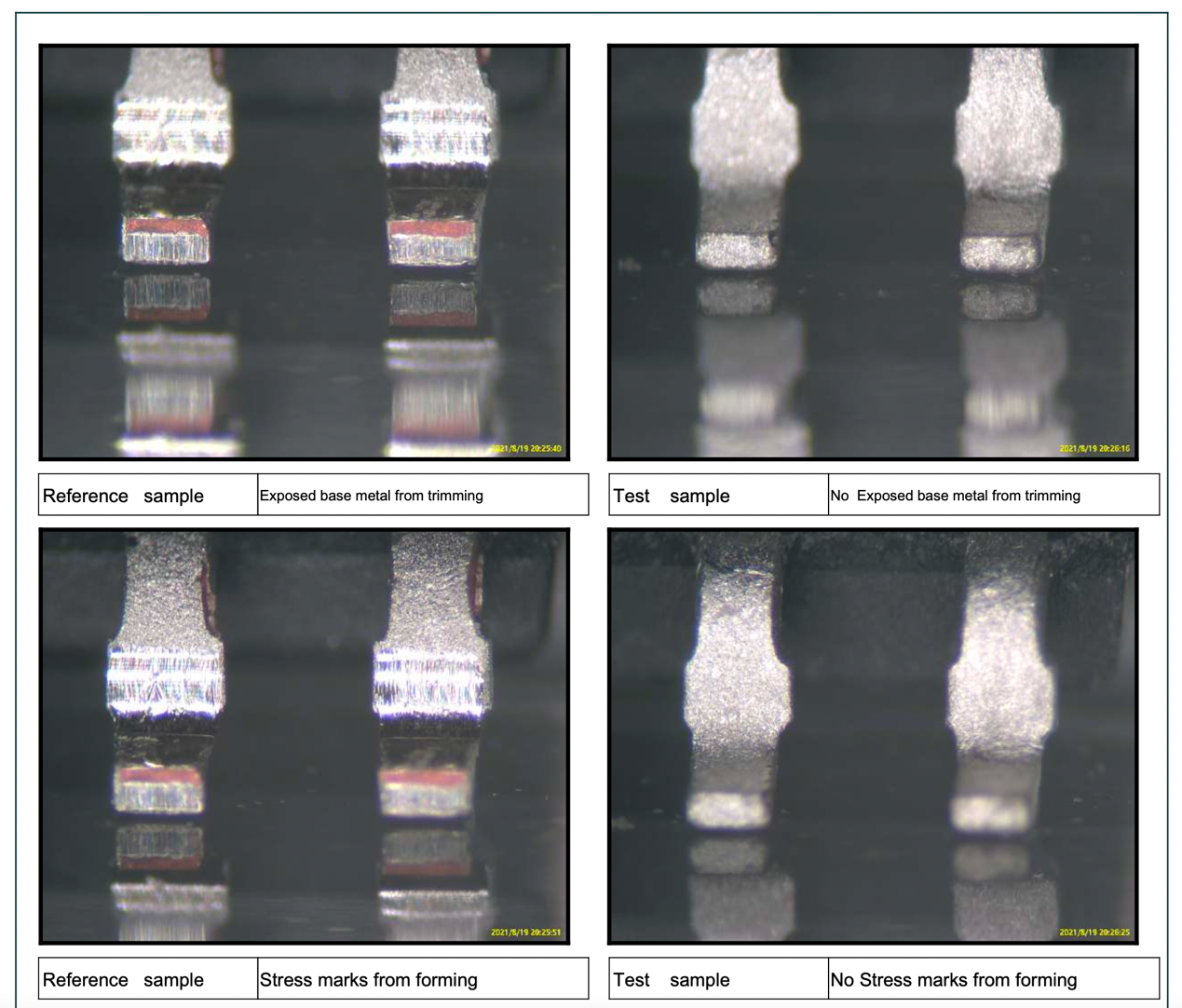

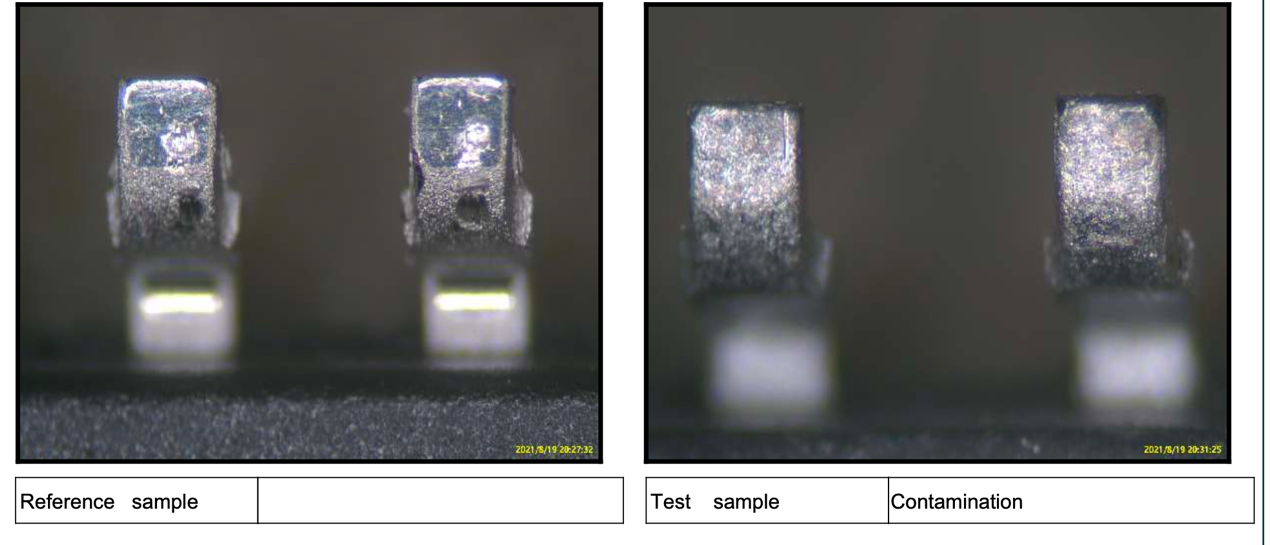

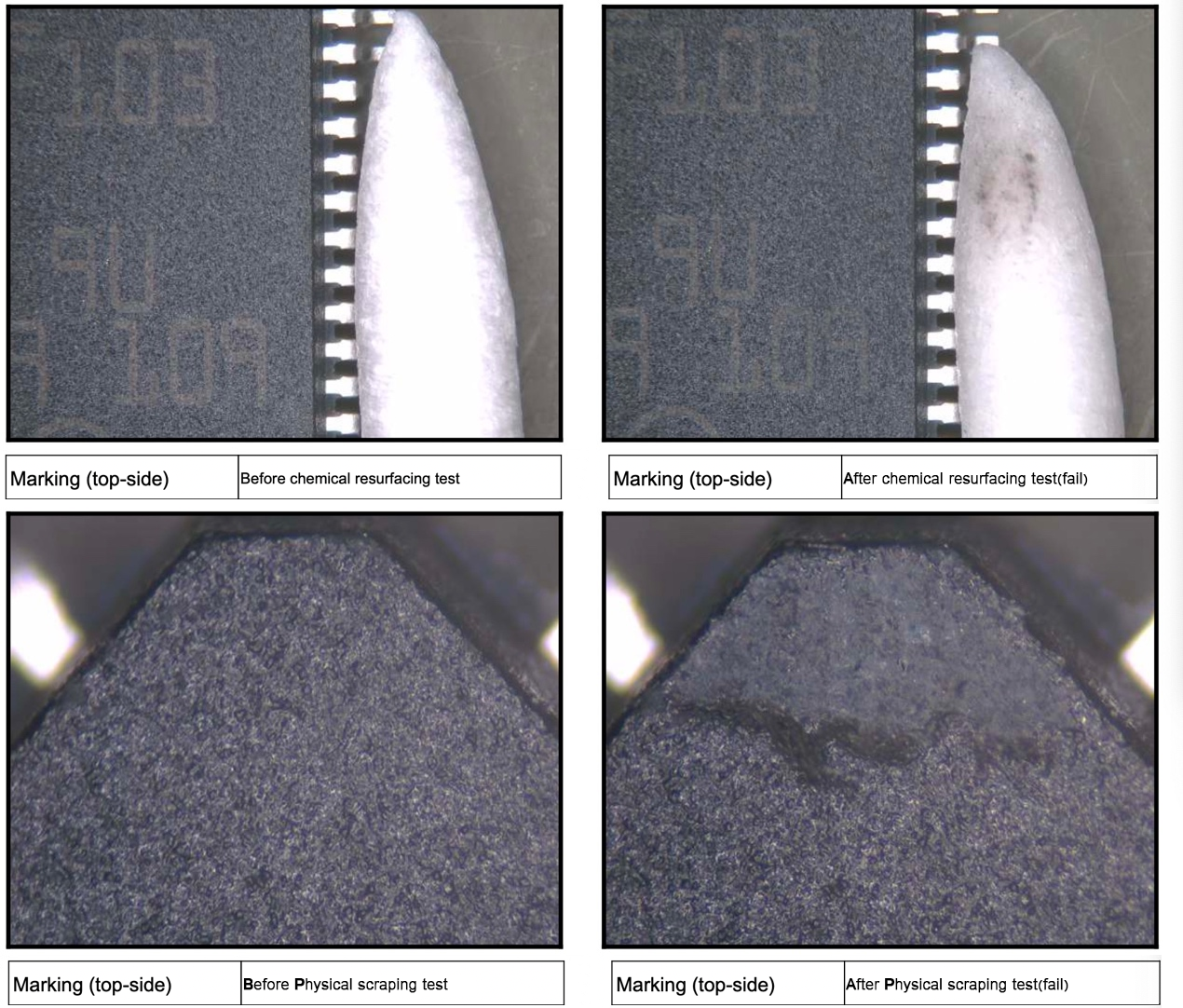

Level 1 Visual Inspection

Genuine

Fake

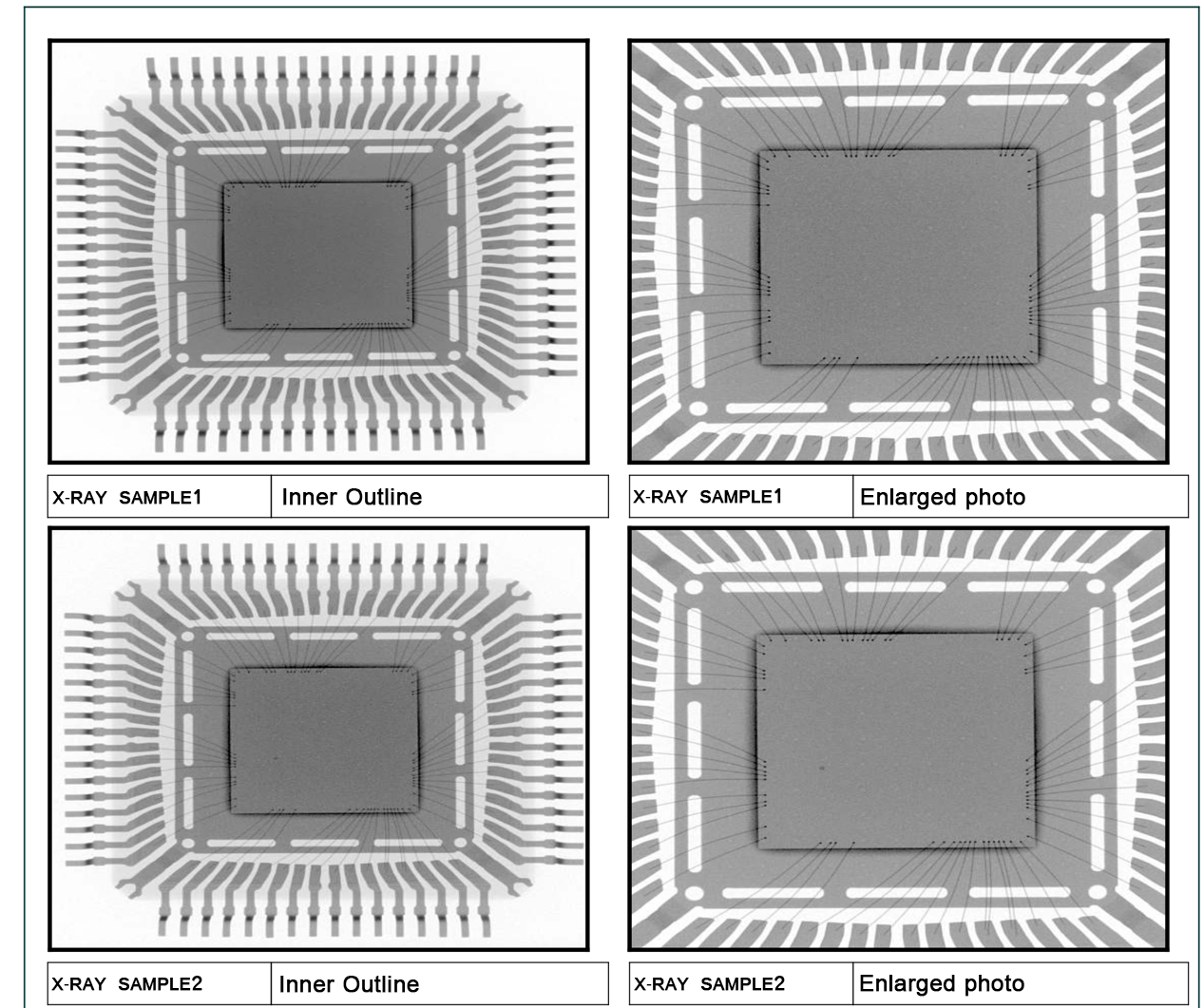

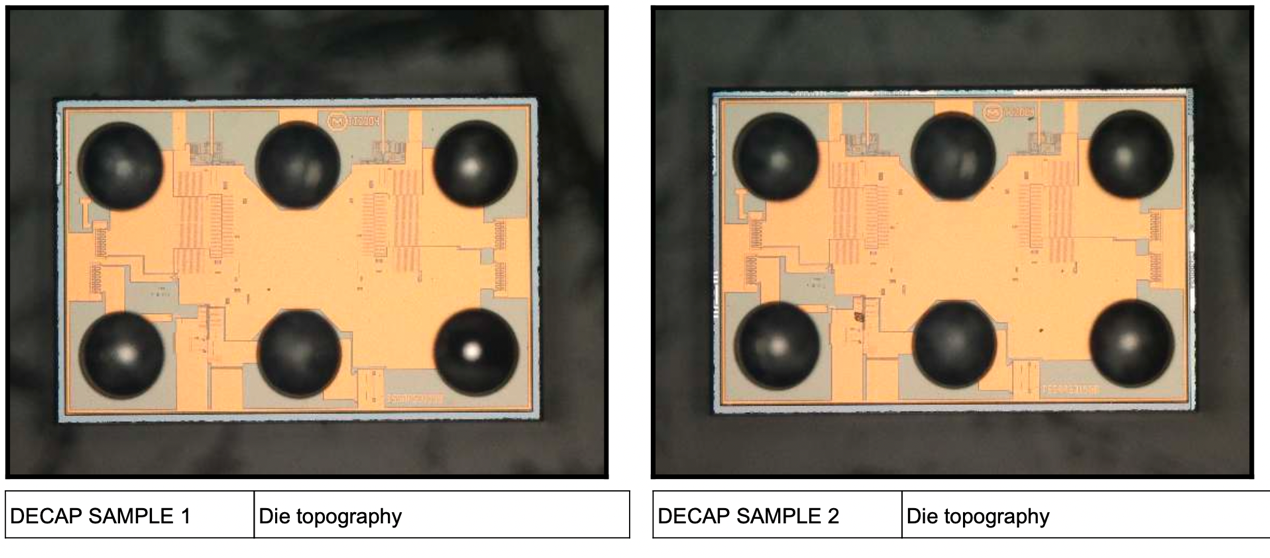

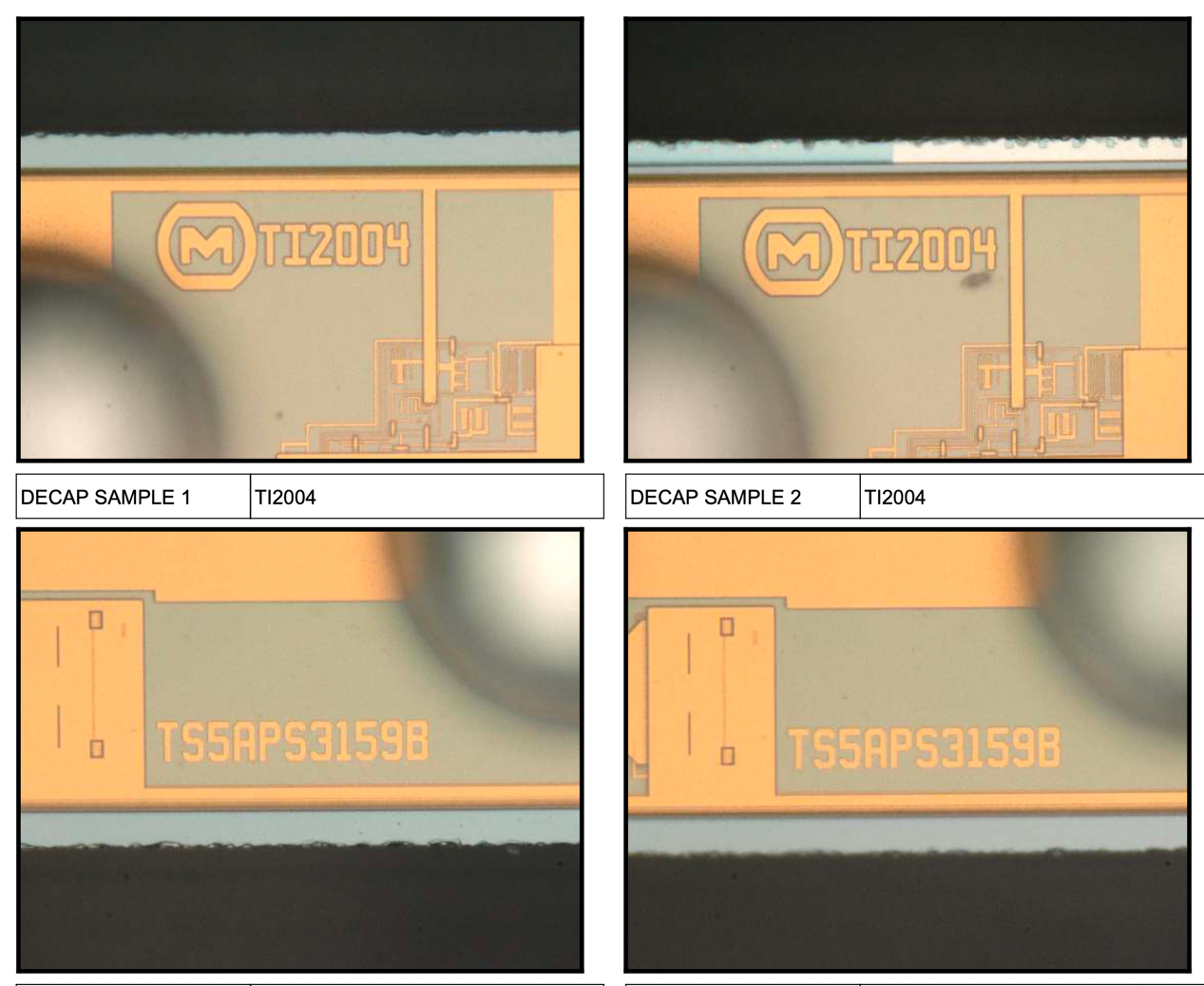

Level 2 DECAP Testing

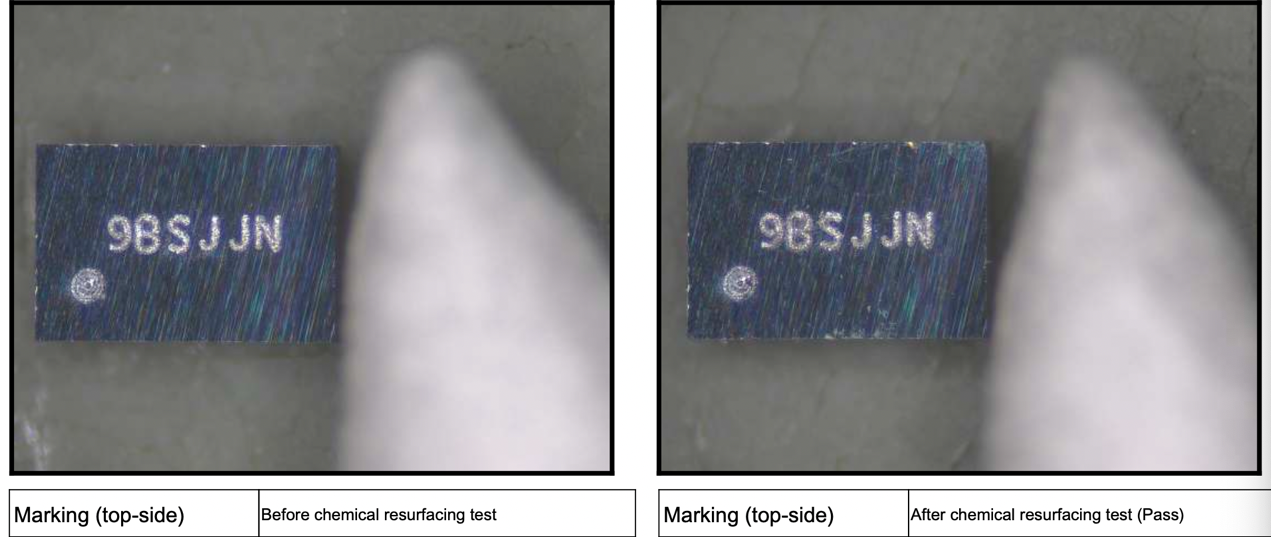

Level 3 Solderability Testing